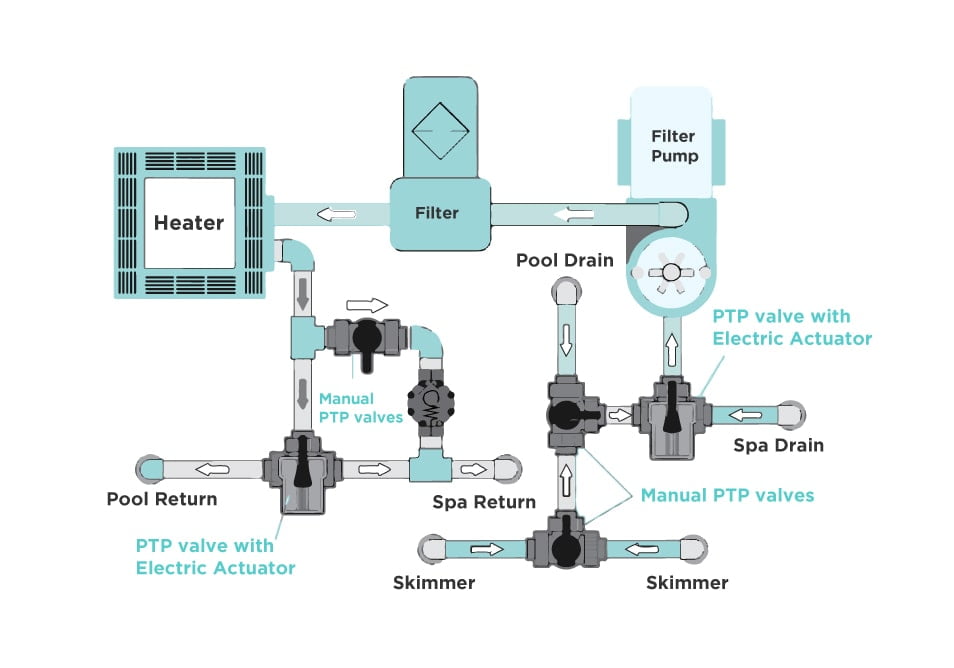

A pool plumbing system is complicated. It acts as the channel for the water to move in and out of your swimming pool through the pump, filter, heater, and other pool features. It ensures there is perfect water circulation. There comes a time you need to divert the water from one area to the other or shut off some pool feature. Also, the plumbing line needs a way to control the water flow direction and make sure it doesn’t flow backward.

That’s where the pool valves come in; they make sure that water flows in the right direction and give you the control of diverting water to another area or cutting off some lines. If you’re not familiar with how they work, don’t worry. This post is here to shed some light on what they are, the different types your swimming pool system might be using, and their functions. Read along.

Things to Keep in Mind When Working With Pool Valves

It’s always best to label the pool plumbing line to know what the valves do when turning them on and off. Usually, the plumber should label them for you, but if by any chance they weren’t labeled, the responsibility will fall to you to mark them out. If you’re not up to the task, you can hire a pool expert to help you out.

When handling the pool valves, you want to make sure your pool pump system is completely off. It will help if you reduce the pressure before trying to divert the water flow. Why? There is a chance of blowing out some pipes, joints or damaging the O-rings with the instant pressure build-up.

What are the Valves on Your Pool?

Pool valves are part of the pool water filtration and circulation and play a key role in maintaining a healthy swimming pool free from debris and contaminants. They ensure the water flows in the right direction. The valves are of various types, with every kind having its functionality. The most common valves available in the most swimming pool include:

- Multiport Valves

- Diverter Valves (2-Way and 3-Way)

- Check valves

- Valve actuators

- Ball Valves

1) Multiport Valve

Multiport valve is found on most sand or de filters. It has a rotating handle on top, allowing you to set it to various positions. Most sand filters have a 6-position multiport valve, but there are some with seven positions.

a) Filter position

The filter position is the most used in both sand and DE filters. When you set the valve to the filter position, the water from the swimming pool travels into the filter through the multiport valve and pushes down through the filter media (sand or DE). It gets filtered, and when it reaches the filter bottoms, it travels through the literals up via a standing center piper, back to the swimming pool.

b) Backwash position

The second place you can move the handle to is the backwash position. As the name suggests, the position directs water from the swimming pool into the filter via the multiport valve through the central standpipe, up through the sand, and out through the drain. That allows the water to push all the dirt out of the pool filter, cleaning it. It’d be best to use a backwash hose to direct the water to an ideal spot.

c) Rinse position

After backwashing your sand filter, it’s always good to rinse it to be sure all the dirt is out. You can do this by setting the multiport valve to the rinse position. It’s a way of resetting the sand bed. When in this position, the pool filter works the same way as the filter position, but instead of allowing the water to get back to the swimming pool, it flows out through the backwash port and out through the drain hose.

d) Waist position

The waist allows the water to flow out of the swimming pool directly to the backwash port and through the drain without entering the pool filter. It’s a handy position mainly used to drain pool water quickly or can be used when vacuuming a lot of dirt that you don’t want entering your pool filter.

e) Recirculate position

As the name suggests, recirculate takes the pool water out and back without entering the filter. It’s for circulating the pool water when the need arises. You can use it to distribute chemicals in your pool without putting any strain on the pool filter.

f) Closed position

Then there is the closed position that closes all the inlets and outlets to the multiport valve off. It makes sure no water passes through the valve. It’s a position you might never use, or you will rarely use.

g) Winterization position

For those filters with a 7-position multiport valve, there is the winterization or winterize position. It keeps all the valves open during winter to allow condensation building up in the tank to evaporate during the cold months.

2) Diverter Valves

The following types of pool valves you will come across are the diverter valves. They allow diversion and redirection of water flow from one area of the pool plumbing system to the other. There are two types of diverter valves:

a) Way Diverter Valve

A 2-way valve has controls plumbed in from the valve’s both sides. It allows the water to flow to or from one port. There is full water flow when you set the ‘off’ position away from the plumbing line, or the valve’s handle is horizontal to the plumbing line. You can also get a partial water flow when you set the valve handle at an angled position.

b) Way Diverter Valve

A 3-way diverter valve is very similar to a 2-way valve. However, this one gives offer some more flexibility. You can use a 3-way valve to control two inlets and outlets. It allows you to close one valve’s end fully or partially while allowing the other ports to stay open. It’s mostly found on the main drain and skimmer controlling point to allow you to fully or partially close either when the need arises.

3) Check Valve

Another type of pool valve your pool plumbing system needs is the check valve, which is probably one of the most important pool valves you should have.

Their primary purpose is to prevent water backflow in areas where the pool water MUST NOT move backward. When the pool pump is off, nothing stops the water from flowing in reverse.

However, a check valve can ensure that it never happens to prevent any mayhem that could happen in your swimming pool.

There are a couple of areas where it’s most crucial to use a check valve, including the following:

a) Automatic Chlorinators

If your pool uses an automatic pool chlorinator or a salt-chlorine generator, it’s probably the last piece of the pool equipment the water flows through on its return to the swimming pool. When chlorine is generated, it’s in high concentration and must be diluted in the pool. If the high-chlorine water flows backward, its concentration can potentially damage your pool equipment.

However, installing a check valve between the chlorinator and its equipment can prevent the high-concentrated chlorine water from flowing backward. So, if you were to shut off the pump, then the water wouldn’t flow back. That will protect the pool filter, heater, and other equipment sensitive to high concentration chlorine.

b) Raised Pool Pumps

You can also use a check valve on the incoming suction line to form the pool filter pump. For those filter pumps raised more than 24” from the water surface, they should be installed directly against the pump (12”-18” in front of the intake) to allow optimal pump priming. If you don’t have enough horizontal space, you can install the valve vertically.

c) Solar Pool Heaters

Solar heaters mounted on the roof require check valves on their intake and return pipes. When placed on the plumbing line leading to the solar panels, the check valve prevents the solar system from draining down when the pump is off. When installed on the return line, it prevents water from cycling back to the solar panels when the solar heater is off.

d) Raised Spas

Water uses gravity to seek its level. When a fountain, water feature, or spa is placed at a high level of the water surface, it’ll naturally gravity-drain into the swimming pool when the pump isn’t running.

A check valve can be used to keep these shared features from losing water when the pool pump is off. It can also help prevent deck jets, waterfalls, and wall fountains from draining when not in use.

e) Ozonators

When using an Ozonator, there must be a check valve to prevent the ozone concentrated water from back flowing to the pool before it’s diluted. That’s why Ozonator manufacturers recommend replacing the ozone tubing and its check valve regularly to ensure the gas flow in one direction only and block the water from backing into the production chamber. We recommend buying your favorite at super low prices with free shipping, https://www.fakewatch.is and you can also pick up your order at the store on the same day.

4) Valve Actuator

The next type of valve is the valve actuator, a mechanical device that uses power to operate the pool plumbing valves. It automates the whole ON-OFF valve operations with a push-button command.

With a valve actuator installed, you don’t have to walk over to the pool valve area to turn the valve manually handles to control or redirect the water flow. All you need is to press a button to select the valve you want close or redirected, and it will be done for you.

You can even use it to control the water features in your pool with a push of a button. It’s a way of saving time and frustrations. It’s simple to set it and forget. However, you will need a high upfront cost when purchasing and installing the valve actuator.

5) Ball Valve

Lastly, there is the ball valve, which works similarly to a 2-way diverter valve. It’s designed to allow you to switch off the line or redirect the water from one area to another. Usually, the line will be completely open when the valve if you set the ball valve handle perpendicular with the plumbing line and off/restricted when it’s in the horizontal position.

Frequently Asked Questions

How do you know if a pool valve is open or closed?

Most valves from various manufacturers have the same design. In most of them, you’ll notice an off word on the side adjacent to the handle. Typically, there will be a white mark pointing to the ‘off’ sign where the pointer or the ‘Off’ sign shows you the closed pipe.

For example, in a 3-way diverter valve controlling the main drain pipe and the skimmer pipe, when you turn the valve such that the off word points to the main drain, you’ll have it shut off, leaving the skimmer on vice versa.

The correct water flow into your pool pump is when you leave the two plumbing lines (the main drain and the skimmer lines) open simultaneously.

However, it’s different with a ball valve. Typically, the valve handle should be perpendicular to the pipe when the valve is open and horizontal when it’s closed.

How do you replace a check valve?

Get a check valve replacement. You can buy it directly from the worn-out valve manufacturer to make sure it fits properly. You can also search local or online stores for an exact model.

Once you have an operation replacement, ensure the pool water system (pump) is switched off. Open the clear cover by unscrewing the set of screws holding it in place. Take out the wrong valve and set it aside.

Pick the new replacement and place it in the same orientation as the one you’ve removed. You want to hand-screw the screws to avoid over tightening them as that might compromise the O-ring. Also, try screwing the screws from opposite sizes.

I mean, if you screw in one of the screws on your side, the second screw you tighten should be on the opposite side. That way, you’ll balance the O-ring to make sure it sits nice and tight.

But, how can you tell if the check valve is bad?

Typically, the transparent cover will get clouded, the O-ring might go bad, the flapper spring might lose its tension, or the flapper handles might break.

Leave a Comment