If you are looking for a new pool system to install in your home, it is best to know some knowledge of each part to understand what to choose from when talking with a plumber about installing one at your house specifically designed for your needs.

There are several different types of systems and sizes depending on how big the pool will be once installed, along with where on your property it will be placed. Many people also opt to upgrade their current system by switching out specific components such as changing valves.

Some pieces of the poll plumbing might need replacing due to high amounts of use or age over time, not offering adequate functionality anymore if they were installed when the pool was first made.

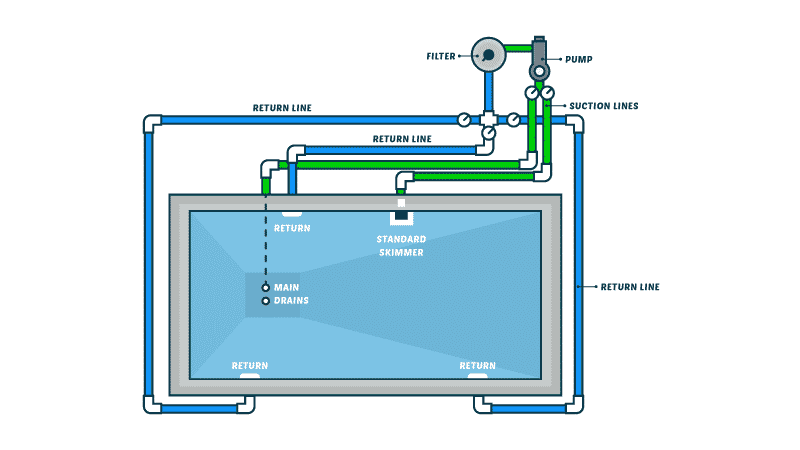

Parts of a pool plumbing system

1. Skimmer(s)

A skimmer is a rectangular part on the pool walls near the water surface. It skims surface debris, such as leaves or bugs, off the water before sinking to the bottom and decomposing faster than if left in the water.

It can be installed at one end or across a few feet of piping for greater suction power to pull in more dirt and debris from your pool water. Some swimming pools have more than one skimmers, which might be installed on one side or opposite walls.

2. Main drain

The main drain is a large-diameter circular or rectangular piece on the pool bottom that sucks the pool water out to the pool pump. Usually, it has a direct line to the pool pump, but you might find it find it connect to the skimmer.

The main drain is mostly used to provide alternative water flow if the skimmer is blocked, protecting the pump from running dry. It does also come in handy during brushing. You can push the dirt towards the drain, and it will suck it out.

3. Valves

Swimming pool valves are small but essential pieces of equipment that help control the amount and direction of water flow in a swimming pool or spa system. It comes in handy, especially when you need to close the main drain and reduce skimmer flow to get more suction for a suction side cleaner.

Here are some types of pool valves that you will come across your pool’s plumbing system.

a) 3-way valve

A 3- way valve is an essential piece of equipment that helps control the amount and direction of water flow between two water lines. It can be used, for example, to reduce the flow of water in one direction or redirect it elsewhere.

- All Valves Available in CPVC or PVC

- Maintenance-Free Diverter Seal

b) 2-way valve

A 2-way valve allows water to pass in one direction and blocks the flow of water coming back. These valves are used on some equipment such as pumps, heaters, or inline filters.

2-way valves prevent back siphoning of pool equipment that could damage it from pressure buildup inside the plumbing system if there’s an interruption in water flow.

- 2-Way PVC diverter valve

- Maintenance-free; high flow rate and fiberglass reinforced handle

c) Gate valve

A gate valve is an essential piece of equipment that helps control the amount and direction of water flow between two pipes. It works by rotating a handle that opens up one-way passages allowing more or less fluid through each opening based on how far the handle is turned.

d) Ball valve

A ball valve works by rotating a handle that opens up one-way passages allowing more or less fluid through each opening based on how far the handle is turned. This kind of equipment can reduce the flow of water in one direction or redirect it elsewhere.

- Socket ends

- Corrosion-resistant PVC

e) Check valve

A check valve helps see and control the flow and direction of water and other fluids through pipes. They work by allowing fluid to pass in one direction without letting it come back. This kind of equipment can reduce the flow of water in one direction or redirect it elsewhere.

I have a complete article on pool valves that you can read to formalize how they work and their purpose in pool plumbing.

4. Pump

The pump is the main component of a swimming pool’s circulation system. A pool pump pulls water into its internal chamber, then pushes it out to the filter and back to the pool through hoses. The impeller inside it helps push water around by creating pressure on one side of the rotating part that forces water through hoses with high velocity.

Different types of pumps depend on how much debris or sand they can handle before being clogged up or damaged. A more powerful pump will have better filtration capabilities but may cost more money for electrical bills. It may wear down some components faster than usual such as diaphragms in valves; even if not used every day, it works harder when filtering dirtier water.

- The Hayward PowerFlo LX Single-Speed 1.5 HP Pool Pump is designed specifically for the...

- Heavy-duty motor offers dependable performance, energy efficiency and quiet operation

5. Filter

The filtration system does the dirty work of removing contaminants from pool water before it circulates back into the pool through the skimmer and main drain. When the pool pump pulls water from the swimming pool through the skimmer or the main drain, it pushes it to the pool filter for cleaning. What comes out of the pool filter is clean water free of microscopic contaminants.

Diatomaceous earth filters are designed specifically for dealing with the fine particulate matter without using chemicals or electricity. They do not clog up as quickly because their pores are much larger than sand filters. That means they can trap more particles per square inch of water surface area before being cleaned out; however, all that trapped dirt needs to go somewhere.

- ECONOMICAL AND EFFICIENT: The Hayward Perflex Extended Cycle Diatomaceous Earth Pool...

- QUICKER CLEAN: Removes even the smallest particles the first time through for a quicker...

6. Saltwater System (optional)

A salt system makes it possible for a pool owner who lives near the ocean with naturally saline (salty) tap water to enjoy swimming in an otherwise untreated body of refreshingly clean seawater instead.

Some coastal areas also use different brackish (mixture of fresh and seawater) sources like estuaries where freshwater drains into saltwater bodies like bays or harbors, but this is less common due to limited land availability.

A saltwater generator or chlorine fed system is usually installed outdoors rather than inside the home.

- FOR SMALLER POOLS: For in-ground pools up to 15,000 gallons and includes Hayward TurboCell...

- NO MORE HANDLING CHLORINE: Automatically converts salt into chlorine, naturally, while...

7. Chlorinator (optional)

A Chlorinator is responsible for adding chlorine to the water. It’s where you can add tablets or liquid bleach to sanitize the pool water. It comes right after the water leaves the pool filter clean of the contaminants.

- Rainbow 320 automatic chlorine/bromine in-line pool and spa feeder

- Holds 11 large or 98 small bromine or slow dissolving trichlor tablets

8. Returns jets

These are the jets that return water to the pool. They can be operated manually by a switch or other device, and they typically have adjustable flow rates and direction of the output.

9. Pool features line

Some pools have plumbing lines that take special water features like waterfalls, slides, diving boards, or other unique elements that make them even more fun to swim in!

What Are Pipe Materials Commonly Used in Pool Plumbing?

When it comes to pool plumbing, you cannot use any pipe material you come across. Certain types are proven to work quite well with swimming pools. They include:

1) Rigid PVC or rigid polyvinyl chloride

Rigid PVC or Polyvinyl Chloride piping is the most commonly used type of plumbing pipe material. It has won its 1st choice selection for its durability, pressure resistance, and insulation properties are critical.

Its ability to withstand freezing temperatures makes it perfect for ground-level use without breaking down under freeze/thaw conditions which would typically cause copper pipe damage during that time period.

The material has become much better environmentally friendly due to better production practices, reducing the number of toxic chemicals used in its manufacture. It is also recyclable, so you can get it back and use it for another purpose after its life cycle with your pool.

It is available in different sizes and can be easily cut to specified lengths. It has become more environmentally friendly thanks to its recyclability. It is also straightforward to work with in terms of installation.

However, it can be susceptible to chemical attacks from pool chemicals and may leak after a few years if not installed properly by an experienced professional.

It is also more expensive than other plumbing pipes but worth the investment because it will last for many decades with minimal maintenance required.

2) Flex PVC or Flexible polyvinyl chloride

It’s another common type of pool plumbing pipe because it can withstand high pressure and has excellent insulation properties. This material has become more environmentally friendly thanks to its recyclability.

However, it can be susceptible to chemical attacks from pool chemicals. Its ability to withstand freezing temperatures makes me perfect for ground-level use without breaking down under freeze/thaw conditions which would typically cause copper pipe damage during that period.

3) High-Density Polyethylene pipe or HDPE pipe

HDPE pipe is a plastic pipe that is used for above-ground pool plumbing. It is commonly thought of as a flexible or corrugated material, but it can also be found in rigid sections. HDPE has good chemical resistance and strength at lower temperatures.

That makes it suitable for outdoor use where the piping may contact chemicals such as chlorine bleach. The thick walls on this product make it more resistant to dents than other types of PVC pipes.

Cross-linked Polyethylene (PEX) pipe, a form of high-density Polyethylene (HDPE) that has been processed to increase its resistance to heat, water pressure, and corrosion by adding cross-links

The connections create an abundance of free electrons, reducing the attraction between the molecules, thereby increasing flexibility and durability. PEX can be used for both hot and cold potable water distribution systems as well as radiant heating.

While it may look similar to black Polyethylene pipes, they are different materials with various applications, including pool plumbing systems.

Although HDPE pipes are more flexible, they do not have as high heat tolerance, making them less suitable for hot water systems like those that supply heated villa spas or swimming pools.

4) Vinyl

This type of piping is not as durable as some other types, but it is cheaper and easier to install since it is more malleable. This kind of material needs regular maintenance checks because it tends to crack & leak over time, especially if exposed to intense sunlight from prolonged hours, which may also affect its flexibility due to high temperatures.

Cracks also lead to water leakage, thus making this pipeless suitable for commercial applications where pools are often used by multiple people throughout the day despite their low price points compared to other materials used for pool plumbing.

However, vinyl piping is relatively easy to work with compared to others since it takes less time and effort to cut through using tools such as pipe cutter or hacksaw. It does not rust either, which makes it a safe choice if exposed to pools containing chlorine, bromine & saltwater. All are corrosive by nature, thus requiring protective measures when choosing pipes, especially PVC types that degrade rapidly.

Lastly, this material has been around since the 1960s, so its another tested option on durability overtime despite being cheaper than steel & copper alternatives

5) Copper

This kind of pipe is well known for its excellent resistance against corrosion, thus making them a popular choice, especially in areas with hard tap water that contains high minerals. If not treated adequately during installation, the minerals can affect metal surfaces, including plumbing systems that use metals as their main components, such as steel and aluminum. Browse our , with a variety of options to suit every taste and budget, https://www.fakewatch.is/product-category/hublot/classic-fusion/ available to buy online.

High-quality grades of copper are also safe alternatives too since they have very low pH levels, which means that they can resist corrosion even in areas with soft water that has low mineral content. It’s also not recommended for underwater applications since it takes too much effort when cutting through using tools such as pipe cutter or hacksaw.

However, this material is relatively expensive to install compared to other materials used for pool plumbing systems. Its high initial cost of purchase and labor costs involved during installation makes it more suitable only for commercial applications where pools are used often.

Lastly, copper piping types aren’t safe around saltwater based pool conditions like vinyl mentioned above because it will rust quickly under these kinds of conditions leading to leaks, especially when exposed directly into water or installed

6) Fiberglass reinforced plastic (FRP)

This kind of piping is the most durable and long-lasting material for pool plumbing systems. The pipes also have excellent resistance against corrosion which makes them an ideal choice around areas with high levels of minerals found in hard tap water

Because it will help protect metal surfaces from rusting so quickly even if exposed directly into the water, causing severe damage to other metals such as steel & copper. But it still needs regular checks for wear, tear & damage, just like vinyl mentioned above, before installing new ones to avoid leaks and cracks due to its flexibility and weight.

This material is also safe around saltwater-based pool conditions like vinyl mentioned above because it won’t rust quickly under these conditions, leading to leaks, especially when exposed directly to water or installed correctly.

FRP piping types are also known for their excellent resistance against damage from ultraviolet rays. That makes them ideal for underwater applications other than other materials such as copper and steel that need insulation protection during installation. They tend to wear out rapidly if not adequately protected before being submerged in water after the process has been completed.

Fittings types used in pool plumbing

Here are the various kinds of fittings that attach different pipes used in pool plumbing:

1. Spigot

Spigot is a male threaded fitting that attaches to a female pipe thread. These are used for the connection of components such as valves, elbows, and other fittings. It is also called a ‘male connector.’ The spigot and unions allow you to connect various components without needing to cut down the pipes.

If you need the pipe length increased, it may be possible for a qualified plumber to add on more pieces using these fittings instead of cutting and re-welding. It’s much easier than having an expert come out every time you want something changed or repaired.

- Widely application: 4 mm thick durable silicone seal gasket for long-lasting, commercial...

- Specifications: size is 3/4 inch, material is PVC, which resists to fading, cracking, and...

2. Union Fitting

Union fitting is a type of coupling joins two tubing pieces by connecting them at different angles using three ports (a middle port with an inlet/outlet on each side).

The tubes can be disconnected from one another without disconnecting the union itself, providing quick access to replace any parts or clean them out.

They don’t use any glue or adhesives, so they provide leak-proof connections when properly installed and connected correctly.

- 2 in. MIP x 2 in. PVC Hi-Temp Union by CMP

- 21063-200-000

3. Elbow Fitting

An elbow fitting (or ‘elbow’) attaches at 90-degree angles to other spigots or unions to change directions when piping needs to go different ways.

They can also connect multiple sections. However, they are not compatible with union couplings since they do not have ports as that type does.

Different sections connected by elbows would cause leaking issues, possibly resulting in damage if left unchecked over time. The elbows can be used to change the direction of where water flows or is stored.

- Replace Hayward SPX1105Z3, SPX1105Z4 hose adapters

- Measures 1-1/2" MIP by 1.5" or 1.25" hose.

4. Cross Fitting

A cross fitting, also called a ‘union tee,’ allows another spigot to connect with two different unions at right angles from one another. This type does not allow for any elbows.

It has three ports instead of just one like on an elbow joint allowing only this kind and no other types. You can only use it when you are using some PVC piping which doesn’t have restrictions concerning what fittings are allowed to be connected.

These parts come in various sizes depending upon your needs, so they can fit many pipe thicknesses too, including schedule 40, 80, 100, and 160s, and be compatible with several major brands that produce pool supplies.

5. End Fitting

An end fitting is another type of connector that attaches to spigot and unions to cap off a section of pipe or tubing when it’s not needed anymore, which you can see used on the last line pictured above. The fittings are also called ‘end caps’ or ‘cap ends.’

They come in male and female variations, depending upon what component they will be attaching to, such as spigots, unions, and elbows.

End fittings allow you to secure any pieces making them safe from damage due to movement either by children who may play near the pool area or by adults moving things around during cleaning routines where there could be accidental bumps into objects if components weren’t properly secured.

6. Test Plug

A test plug is a type of cap for the end fittings that have threads on them where you can screw this in to ensure there are no leaks when it’s not being used anymore, either temporarily or permanently, depending upon your preferences and needs.

If you plan to use something else in its place later, then removing it will be easy too, since nothing is glued onto these types. That means they are easily removable without damage to anything as long as an expert knows what they are doing with plumbing components is done correctly.

This piece comes in all kinds of variations, including bulkhead, flat disk, threaded nipple, rubber plunger style plugs, and others for different applications such as draining water before winterizing or when the pool is not in use.

7. Bulkhead Fitting

A bulkhead fitting, also called a ‘gate valve,’ allows water to flow through it. These are used mainly by plumbers who want to drain down pools before closing them up or during winterizing procedures where there could be frozen pipes that need attention if they were left open and unattended over time.

Damage can occur from this happening, which may require major repairs to fix depending on how long they’ve been exposed without anyone knowing what’s happening inside your home.

These parts come with male threads only, so you will need spigots with female ends when connecting different pieces using this type instead of unions and elbows.

- 【Function】: The lock nut is a reflective threaded secondary head equipped with a...

- 【Material】: The material is PVC, and the applicable model is universal. It can be used...

Pool Plumbing Pipe Sizing

Pipes sizes for pool plumbing are generally made of PVC. Knowing the pipe’s size is essential if you install a completely new system or replace your existing pipes.

Why do pool plumbing pipe sizes matter?

Pipes sizes for pool plumbing because they determine everything related to the pool. Knowing what pipe needs to be used is key if you want your equipment to operate properly and with maximum efficiency. In addition to this, the right pool size help in:

1) Matching pool equipment water flow

The size of the pool plumbing pipe needed is directly related to what equipment you have. If your equipment has a large water flow, you will need larger pipes not to be restricted and lose their strength.

The smaller the diameter of the pipes, the more water flow will be restricted. Pipes’ sizes determine how effectively you’re able to use all of your equipment.

If you want everything in excellent working order with no hiccups or difficulties down the line, knowing what pipes need to be installed is critical!

2) Matching water pressure

Water pressure also needs to be considered when choosing the right size for pool plumbing pipes. When water comes out of the pump, it is under a lot of pressure. Having too small pipe sizes can cause leaks over time caused by extra force building up inside the pipes.

If you have too large of pipe sizes, the water will not get from one place to another quickly enough, resulting in headaches with your equipment.

3) Reducing pool heating costs

Pool Equipment that is too small for your needs will be a massive waste of energy and money, as well. This can also lead to long-term issues with things breaking down because they’re overworked.

Pipes sizes need to match all the other aspects of water flow to make sure everything continues working smoothly throughout its entire life span.

Knowing what kind of pipe size you need makes ordering them from an online supplier like us more straightforward.

What factors affect the pool plumbing pipe size to use?

Pool pipe size selection is affected by some factors; they influence how well they fit within the system. They include:

1) Your pool pump Flow Rate

The flow rate is the amount of water that comes out at a certain time. Most pumps are rated to work within specific ranges.

You should design your plumbing system not to restrict the pump’s ability to meet its full-rated capacity and provide sufficient head for proper operation and safety.

The “full-rated capacity” means how much water can go through the pipes without restriction at the max output from the pump.

2) Amount of water the filter system can handle at a time

The filter system has to be able to handle the amount of water in the pool. If it cannot, you will have problems filtering your pool quickly and adequately. A bigger sized pipe is better suited for handling more water at one time than a smaller size pipe would.

You need that larger capacity when filling up or draining out an entire swimming pool (which happens often). Make sure you get proper measurements on how much water your pump can handle before buying anything.

This calculation also considers any other equipment associated with the pump like valves, pressure tanks, etc. This works correctly if everything is set upright, so make sure to research what all needs to be included here.

3) Consider the booster pump

A booster pump increases the overall flow rate required by equipment after it. You have to reconsider the additional flow rate when working out the ideal pool plumbing pipe sizes.

4) Water features hooked up to the plumbing system (waterfall, slide, or spa jets)

All of these water features will require additional flow, so you’ll need to increase the size of your pool plumbing pipe sizes.

To account for all this, make sure you have a minimum of 20% spare capacity if anything goes wrong with equipment or electrical.

You can always reduce it later if required but adding more is expensive and difficult, involving running new pipes back through walls, etcetera.

5) Number of returns you have on the pool

Each return has its flow rate, which you can use to balance the spa jets, waterfall, or any other feature you want to run off your pool pump.

The returns are sized by their flow rates and must be equal in size to each other – so if one is two inches, they all should be two inches, etcetera.

Common Pool Plumbing Pipe Sizes

In the plumbing world, there are many different sizes of pipe. Pipe sizing can be determined by using this formula:

PIPE SIZE = (GPM x Head Pressure)/100.

For example, if you have a pump that produces 40 GPM at 20 PSI of pressure, your pipe should be equal to or larger than ½”. NPT stands for National Pipe Thread Tapered, and the T represents tapered.

When it comes to threaded fittings such as pipes and elbows, use thread sealant tape along with Teflon paste when assembling all joints.

This will help prevent leakage from occurring over time caused by wear-and-tear and stress on the fitting itself, which eventually them to break. Thread sealant tape is also referred to as Teflon tape.

Standardizing those measurements is essential to ensure that pipes fit together and function as intended. In the United States, some common pool piping size standards include:

Pipe size used on the suction side pipe sizes:

- ½ inch supply pipe is the most commonly used size for pool pumps, typically found at homes.

- ¾ inch supply pipe is slightly larger and better suited to commercial applications such as hotels or large residential complexes.

- Larger pipes can be made by combining two smaller sized (½ and ¾ inch diameter pipes).

Pipe size used between the pump and filter:

- ¾ inch pipe is the most common size.

- If available, it may be possible to use ½ or ⅝ pipe, but this tends to result in lower flow rates and reduced filtration capacity unless multiple pumps are running simultaneously, which can compensate for less than optimal filter efficiency.

- Larger pipes can be made by combining two smaller sized (½ and ¾ inch diameter pipes).

- For cartridge filters with small openings such as DE grids, a larger ID clear PVC hose is sometimes necessary instead of piping between an equipment pad and pool pump. This allows water through while still keeping debris out of the central system where it belongs!

Pipe size used for the return lines:

- If you use a multiport valve or manifold, use the same size for all of your return lines.

- If you are not using a multiport control unit, try to match the pipe size with each plumbing fixture on its separate line. For example, if your house has two bathrooms and both have one sink in them, there should be two plumbing fixtures lined up coming out from behind the wall so they can connect to their pipes leading back down into the pool filtration system.

- When buying PVC piping, make sure it is grey (not white). When choosing which diameter of type L tubing, choose either ½ inch or ¾ inch depending on how much flow rate you want/need through these return lines, as the more significant the diameter, the faster water can flow through them.

Related Questions:

How deep should pool plumbing be?

You want your pool plumbing to be at least 2-feet below the surface. That protects it from shifting when soil slips and also against freezing temperatures and UV rays.

Leave a Comment